MRF/MSW

Eriez sets the bar for metals recovery in materials recycling facilities (MRF) and municipal solid waste (MSW) plants. From the world's best drum magnets to suspended magnets, magnetic pulleys, eddy current separators and more.

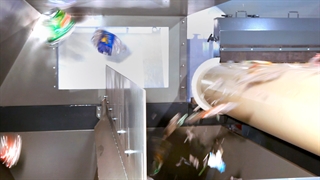

Eddy Current Separators

Separates nonferrous materials using Rare Earth magnets arranged into a super high-speed rotor producing repelling eddy currents. Typically used to separate UBCs, aluminum, brass and copper.

- Separates aluminum and other NF metals

- Eccentric rotors

- Concentric rotors for PET

- Quick Ship models available

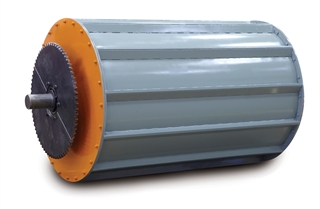

Magnetic Drum Separators

Electro or permanent, heavy-duty, high-volume ferrous separators typically used in ASR/MSW/MRF for metals recycling and recovery. The P-Rex Rare Earth Drum is possibly the strongest permanent magnet on the planet.

- 36 to 84-inch diameters

- 36 to 96-inch widths

- Up to 15-inch magnetic field reach

- Available in permanent or electromagnetic versions

- Ideal for high-volume, heavy-duty applications

Suspended Permanent Magnets

Suspended above a conveyor, these powerful magnets remover steel from conveyed materials with deep burden depths. Typically used to remove damaging tramp metals to protect downstream equipment.

- No operating costs

- Simple installation

- Self-cleaning models available

Magnetic Pulleys

This magnet replaces the head pulley on a conveyor, attracting and holding the ferrous metal to the belt achieving very effective separation.

- Self-cleaning, low cost operation

- 8 to 36-inch diameters

- 12 to 72-inch widths

- Available in permanent and electromagnet construction

- Ideal for high speed, heavy burden depths and hard-to-separate materials

Suspended Electromagnets

- On and off ability

- Wide variety of sizes to cover all conveyor widths

- Five-year warranty on coil assembly

- Self-cleaning or manual-cleaning models

- Six EriezXpress models available in 10 days

Brute Force Feeders

Single-mass mechanical feeder with twin rotary motors well suited for heavy impacting applications. Their simple design makes them reliable, easy-to-repair and handle shock loading well.

- Low cost units

- Easy maintenance

- Good for heavy impacting